Solution Biological Solid Waste

Simple batch fermentation is a good solution when treating biological solid waste that doesn't need much separation.

Accumulated organic substances contain a lot of energy. Superior quality methane gas can be produced from biological solid waste by using dry fermentation technology. Organic materials that can be stacked and vibrated are used by this technology to generate energy and up to 50% of the biomass can be dry substance in order to produce biogas. Valuable compost by-products that originate from biomass processing can also be used as organic fertiliser in the agricultural and horticultural industries.

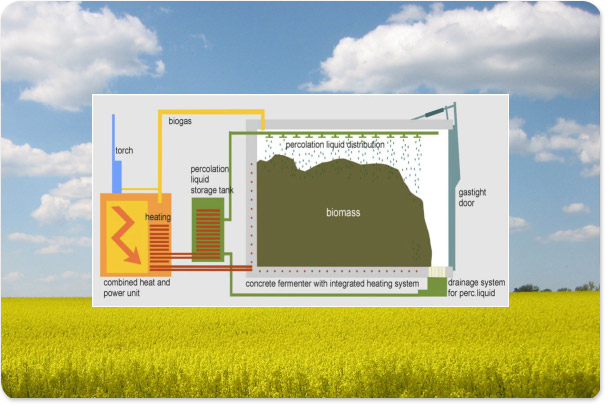

The dry fermentation process is a single-stage batch process for biogas generation from biomass with a high dry matter content. The organic matter is inoculated with substrate that has already been fermented. It is then filled into the digester and fermented under airtight conditions. Continual inoculation with bacterial matter occurs through the re-circulation of percolation liquid, which is sprayed over the organic matter in the digester. No stirring of the organic matter is necessary during the dry fermentation process, as is needed in conventional wet fermentation systems.

The temperatures of the process and of the percolation liquid are regulated by a built-in floor heating system in the digester and a heat exchanger in the tank that acts as a reservoir for the percolation liquid.

The different stages of degradation (i.e. hydrolysis, acidogenesis and methanogenesis process) take place in the same digester, which has a lot of advantages in comparison to other systems. Usually considerably more expense is involved in respect to the process itself and in respect to the mechanical technology behind it, which in turn has an adverse effect on process energy consumption and on maintenance costs.

During the fermentation process, no further mixing, pumping or stirring is necessary inside the digester.

Therefore, dry fermentation technology requires only a low input in respect to process and mechanical demands. In contrast, conventional liquid fermentation systems require a large amount of process energy during operation.

The highly specialised and unique BEKON process technology of dry fermentation requires an extremely low energy input.

- Economic Profitability

- Agriculture

- Municipal Solid Waste

- Biological Solid Waste

- Dry Fermentation